Modern Technologies in Automobiles

(Hasan Amjad, Muhammad Haseeb Shahzad, Muhammad Hussain & Muhammad Taimoor)

Abstract:

1. Introduction and Background

It began when people realized animals could carry them

from one place to another. As the centuries rolled by, they used this mobility

to expand our horizons. While, at the same time seeking even better ways to travel,

they harnessed the power of steam and began to replace animals with engines but

it was not until the development of the internal combustion engine and the

discovery of tools of oil, deep in the earth that we were able to achieve a

basic improvement in individual transport. In 1886, two vehicles were unveiled

only months apart by German engineers, Karl Benz and Gottlieb Daimler-the

automobile was born. Gottlieb Daimler was the first to see a wide variety of

uses for the gasoline burning internal combustion engine. He tried it first in

a motorcycle, and when that was a success he was ready to install his engine in

a carriage. At the same time Karl Benz, working only 60 miles away was

developing his own vehicle. But while Daimler was installing his engine in a

carriage, Benz was creating the world's first automobile from scratch. It was

successfully driven in late 1885 and patented on January 29th automobile

Daimler's vehicle made its appearance.

The first automobile was manufactured, but still a

much more was needed to be done. The automobiles had to still go through the

decades of evolution. As the time passed by, the challenges for the automobiles

manufacturers were raised. Engineers started working on the ways and

technologies that could surpass the standards, and hence a new era of

technologies was started. Many technologies were introduced that could enhance the

efficiency and working of the systems.

This report briefly presents some of those modern automobile

technologies i.e. Hybrid Technology, CVT system, GDI, EFI, Turbochargers, that

are being used, their need, importance and impact on the system and the

environment.

Modern Technologies

2. Dual Fuel System

|

Figure 2.1-Modern

dual fuel engine

|

e

|

In Dual fuel system, two fuels

are used together at the same time in a mixture. However, it usually cranks up

on one type of fuel and a governor built in the system is used to gradually

introduce the secondary fuel source until optimal mixture of these two fuels is

achieved for efficient running of the vehicle. Dual fuel system is capable of

operating on one fuel at a time in the absence of other fuel source but in many

dual fuel engines, from the combination only one fuel is capable of starting

the engine. Thus in order to initiate the engine that particular fuel must be

available for consumption.

|

Figure 2.2-Schematic diagram of Diesel Natural Gas

Engine

|

All

duel fuel systems do not use a diesel-natural gas mixture. Some, such as the

E85 compatible vehicle, consume a mixture of ethanol and gasoline. The optimal

mixture of these fuels is 85 percent ethanol to 15 percent gasoline. Dual-fuel

systems are also used for non-transportation engines, including generators and

drilling rigs. Fewer consumer products use dual-fuel systems because most of

these engines are used in industrial applications and as emergency power back-up

systems.

There is a big difference between

dual fuel system and bi-fuel system. In case of dual fuel system fuel are used

in a mixture but in case of bi-fuel system two fuels are available for

consumption separately. In bi-fuel system, there is switching between two fuels

so that

engines always operate on most efficient fuel according to condition.

engines always operate on most efficient fuel according to condition.

2.1 Working

Reciprocating internal combustion engines are generally

divided in two categories, compression-ignition (CI) and spark-ignition (SI)

engines:

• In CI engines

(diesel engines), air is compressed at pressures and temperatures at which an

easily ignitable fuel fires spontaneously when injected and burns progressively

after ignition.

• Whereas, SI engines (Otto

engines) running according to the Beau de Rochas cycle, the carbureted mixture

of air and gaseous or gasified fuel which does not fire easily (high octane

index), is compressed under its ignition point, then fired at a chosen instant,

by an independent means.

In dual-fuel engines both types

of combustion coexist together, a carbureted mixture of air and high-octane

index gaseous fuel (natural gas) is compressed and then fired by a small liquid

fuel injection which ignites spontaneously at the end of compression phase. The

advantage of this type of engine resides in the fact that it uses the

difference of flammability of two fuels. In case of lack of gaseous fuel, it is

possible to run according to the diesel cycle; switching being possible when

running and without load variation. The disadvantage is the necessity to have

liquid diesel fuel available. Theoretically, the liquid fuel quantity necessary

to fire is tiny (less than 1 %), but, it is not possible to inject with the

given pump and injectors assemblies fuel quantities varying from 1 to 100 %. If

we do not want the material to be doubled, we must be satisfied by injection of

the minimum possible quantity of standard diesel fuel.

·

Economic

benefits: As the cost of diesel fuel rising, and

dual-fuel engines considerably decreasing diesel fuel usage, converting an

engine to operate primarily on a cheaper gaseous fuel is economically

attractive. Moreover, spark plugs and an ignition system are not required,

eliminating the costly spark plug maintenance associated with traditional

natural gas engines, which helps to further reduce overall cost of operation.

Depending on the expected number of running hours and the price of diesel and

gaseous fuels, the up-front installation cost of retrofitting an existing

diesel engine to dual-fuel operation can be recovered quickly.

·

Environmental

benefits: Gaseous fuels and

natural gas in particular are much cleaner than diesel. Diesel engines that

have been converted to dual-fuel operation have exhibited significant reduction

in NOX and CO2 over their original diesel operation. This

is more important in areas with increasingly tough emissions regulations. In

addition, on-site diesel storage capacity can be minimized.

·

Technical

benefits: Retrofit systems can be

installed in the field quickly, reducing engine downtime. No modifications are

required to the core engine or to the factory fuel management system. With the

engine’s main fuel becoming gaseous fuel rather than diesel and the electronic

control system maximizing fuel efficiency, installing an alternative fuel

system enables the on-site diesel supply to last much longer, extending engine

uptime without compromising performance.Replacing diesel

fuel with natural gas typically extends engine maintenance intervals and

overall engine life. For example, life expectancy of cylinder-head valve seats

is improved due to the cleaner combustion that gaseous fuel exhibits over

diesel. Benefits of the factory diesel engine, including hardware ruggedness

and operational efficiency, are maintained. Returning to operation on 100%

diesel fuel is possible at any time.

·

Safety: Gasoline or petrol is an easily ignited volatile

fuel. While diesel fuel is less volatile, it presents the same storage and

handling problems. Comparatively, natural gas exhibits many different

characteristics. It is buoyant at temperatures above -160 F, does not pool on

the ground, and dissipates rapidly in the atmosphere. It is nontoxic,

noncorrosive, and environmentally safe.

2.3 Applications of Dual Fuel Engines

Dual fuel natural gas/diesel

engines are becoming popular in many parts of the world. The more expensive,

sophisticated computer control systems are being introduced successfully in

North America and Australia and are being tested in European in anticipation of

market entry. But their use in other parts of the world is expanding,

particularly in Latin America, India, Pakistan, China and other parts of Asia.

They tend to be used in large vehicles such as buses and refuse trucks, but

also have applications in smaller commercial diesel engine vehicles.

2.4 Importance of Dual Fuel Engines Availability

Diesel engines can be converted

as dual fuel natural gas engines relatively easily because typically there are

no changes in the engine compression ratio, cylinder heads, or basic operation

as a diesel cycle engine. Even the sophisticated computer controlled dual fuel

systems are being developed as ‘bolt on’ technologies that can be removed if

necessary, to resell the vehicle as a normal diesel engine. These conversions

are easy to install and easy to maintain. This flexibility makes these engines

very useful in many global markets

3. Hybrid Technology

The increased

awareness that the world’s energy resources are limited has stimulated many

countries to reexamine their energy policies and take measures in eliminating

waste. It has also sparked interest in the scientific community to take a

closer look at the energy conversion devices and devise ways to develop new

techniques to utilize the existing limited resources.

This led to

the development of the most efficient and energy conservation system, Hybrid

System. A hybrid car is one that uses more than one means of power transmission

i.e. combination of an internal combination engine (petrol or diesel engine)

with an electric motor. ("Hybrid Vehicle" 2018)

3.1 Working of Hybrids

Hybrid cars

have a conventional engine (an I.C Engine), an electric motor and a battery.

These automobiles operate either on engine or an electric motor a combination

of both.

|

Figure 3.1-Schematic Diagram of Hybrid Car

|

The above Figure

illustrates the schematic diagram of a hybrid car. There as an engine which

runs on fuel. In addition to the transmission system the engine is also attached with the generator. When

the car is running of the engine, meanwhile the generator produces electricity

and stores in a lithium battery. This battery can then be used to run the car.

Thus, the car has two transmission systems, one which is connected with an

engine and other with the electric battery.

3.2 Types of Hybrids

Based

upon the working the hybrid technology has following sub types ("What Is A

Hybrid Car And Should You Buy One?" 2018)

3.2.1

Parallel Hybrid Cars

3.2.2 Range

Extended Hybrid Cars

3.2.3

Plug-in Hybrids

3.2.1 Parallel hybrid cars

These are the most common type of hybrid. The car’s wheels can be powered

in three different ways:

·

Directly by the

engine

·

By the electric

motor alone

·

Both power

sources working together.

|

Figure 3.2-Schematic Diagram of Parallel Hybrid

|

Application

Toyota also

uses this system in the Yaris and Auris hatchbacks and Prius+ MPV hybrids.

Similarly, Audi, BMW, Mercedes-Benz, Land Rover, Citroen, Lexus, Peugeot,

Porsche and Volkswagen work on the same basis.

3.2.2 Range extender hybrid cars

·

Use their

conventional engine to produce electricity for a generator that recharges the

batteries

·

The engine does

not drive the car it only charges the batteries.

·

The Car is run

by electric motors.

Applications

The BMW i3

with Range Extender is one of the examples. The Honda Jazz Hybrid is another

one.

3.2.3 Plug-in hybrids

·

The type of

hybrid can be plugged into an electric outlet to recharge their batteries,

·

The batteries

can be charged on the move

·

They have a conventional

engine but also have larger batteries than regular hybrids and can drive longer

distances

·

Travel up to 30

miles on electric power alone

|

Figure 3.4-Schematic Diagram of Plug-in Hybrid

|

Applications

There are a growing number of plug-in hybrids on offer, including the

Mistubishi Outlander, Toyota Prius and Volvo V60.

3.3

Advantages:

· Environmentally Friendly:

Produce less emissions and harmful gases that pollute the environment, as

their run on electric supply.

· Less dependence on Fossil Fuels:

A Hybrid car requires less fuel to

run which means less emissions and less dependence on fossil fuels. This in

turn also helps in reduction of the price of gasoline, and decreases our

dependency on these fossil fuels.

· Regenerative Braking System:

Hybrid cars have Regenerative

Braking System i.e. each time brake is applied while driving a hybrid vehicle

recharges battery a little

· Built from Light Materials:

Hybrid cars are made up of lighter

materials which means less energy is consumed to run. The engine is also

smaller, lighter and compact which also saves much energy.

4. Variable Valve Timing (VVT):

The valves in

an internal combustion engine are responsible for controlling the intake and

exhaust gases into and out of the combustion chambers. In other words, valves

are lungs of an Internal Combustion Engine. The timing, duration and lift of

these valves is significant and plays principle role in engine’s performance.

In an engine,

during the intake the piston moves from the TDC to BDC, intake valve open and

air flows into the engine. Then in the compression stroke the intake valve

closes and gas is compressed. During the power stroke the piston moves towards

the BDC. At last, exhaust valve opens and gas is expelled out. But,

in actual case, the valves do

not open/close at dead center positions but open/close at some degree on either

side of the dead centers. The opening of valve occurs earlier and the exhaust

continues even at later crank angles. This is done to draw more air in the

intake stroke and thus increases engine’s performance.

In this case an engine will have a period of "valve

overlap" at the end of the exhaust stroke, when both the intake and

exhaust valves are open. The intake valve opens before the exhaust

gases completely leave the cylinder, and their velocity aids in drawing in

the fresh charge. Engineers aim to close the exhaust valve just as the fresh

charge from the intake valve reaches it, to prevent either loss of fresh charge

or un-scavenged exhaust gas.

|

Figure 4.1-Valve Timing Diagram

|

4.1

Need for Variable Valve Timing

Without variable valve timing, the valve timing would

be the same for all engine speeds and operating conditions. For instance, the

engine running at a higher rpms it

needs to draw more air, but the intake valves may close before enough air has

entered each combustion chamber, reducing performance of the engine. So, a

system must be introduced which could alter valve, depending upon the speed and

operating conditions. An engine equipped with a variable valve timing actuation

system is freed from constraint, which allows performance to be improved over

the engine operating range.

In automobiles, the opening and closing of the valves

is controlled by camshafts. The cams lift the valves for a certain period of time

during each intake and exhaust cycle. The valve timing, relative to the

position of the crankshaft, is important. The camshaft is driven by the

crankshaft through gears, timing belts or chains. ("Variable Valve

Timing" 2018)

4.2 Valve Timing Terminologies

4.2.1

Valve Timing: At

what time during the engine’s working, the valve will open

4.2.2

Valve Duration: For

how long the valve will open

4.2.3

Valve Lift: How

much valve will move above valve seat

4.3 Methods for implementing Variable Valve Timing

4.2.1 Cam switching

·

Uses two cam

profiles, with an actuator to swap between the profiles (at a specific engine

speed).

·

Provides

variable valve lift and variable duration.

The drawback

is adjustment is discrete rather than continuous.

Application

Honda's VTEC system. VTEC

changes hydraulic pressure to actuate a pin that locks the high lift, high

duration rocker arm to an adjacent low lift, low duration rocker arm(s).

4.2.2 Cam phasing

·

Most common

used method for implementing Variable Valve Timing.

·

Uses a device

called variator which allows continuous adjustment of the cam timing

The draw back

of the system is that the duration and lift cannot be adjusted.

|

Figure 4.3-Cam Phasing

|

Applications

Mostly automobile’s

manufacturers use this method of VVT.

4.2.3 Oscillating cam

·

Uses an

oscillating or rocking motion in a part cam lobe, which acts on a follower.

·

Follower then

opens and closes the valve.

·

Some

oscillating cam systems use a conventional cam lobe, while others use an

eccentric cam lobe and a connecting rod.

·

The major

advantage is adjustment of lift and duration is continuous.

In these

systems, lift is proportional to duration, so lift and duration cannot be

separately adjusted.

Applications

The BMW

(valvetronic), Nissan (VVEL), and Toyota (valvematic) oscillating cam systems

act on the intake valves only.

4.2.4 Eccentric cam drive

·

Eccentric cam

drive systems operate through an eccentric

disc mechanism

·

The mechanism

slows and speeds up the angular speed of the cam lobe during its rotation.

·

The advantage

of this system is that duration can be varied independent of lift.

The drawback

is two eccentric drives and controllers are needed for each cylinder, which

increases complexity and cost.

Applications

MG Rover is

the only manufacturer that has released engines using this system.

5. Exhaust gas recirculation (EGR) system:

5.1 Background:

In case of complete combustion in

an internal combustion (IC) engine the only products which will be expelled out

from exhaust are water vapors and carbon dioxide. Both of these products are

harmless. CO2 is an inert gas and is not directly harmful to human

beings. In reality, air-fuel mixture does not burn completely and incomplete

combustion generates several harmful products (i.e. pollutants). Nitrogen oxide

(NOX) is one of these pollutants. Prolonged exposure of these oxides

of nitrogen is dangerous to health. Nitrogen and oxygen react at very high

temperature. High peak temperature and availability of oxygen in the engine

cylinder are main cause of NOX formation. In the present of oxygen inside the

combustion chamber at high combustion temperatures the following chemical

reactions will takes place behind the flame. ("Exhaust Gas

Recirculation" 2018)

N2 + O2 >

N2

+ 2H2O >

Balanced chemical equations show that a significant

amount of NO will be formed at the end of combustion. The majority of NO

produced will however decompose at the low temperatures of exhaust. But, due to

very low rate of reaction at the exhaust temperature, a part of NO formed

remains in exhaust. The NO formation will be less in rich mixtures than in lean

mixtures. The concentration of oxides of nitrogen in the exhaust is closely

related peak combustion temperature inside the combustion chamber.

In order to control the amount of NOX

forming during combustion oxygen content resent in the cylinder and temperature

of the cylinder should be reduced. There are number of ways to do so. Among

these one method is to introduce an inert gas or non-combustible substance in

the engine cylinder which will perform dual function. It will take some space

in the cylinder volume and thus less amount of air (oxygen) will come inside

the cylinder during intake stroke. Secondly, it will absorb some of the heat

produced during the combustion. Reduction in two main reasons of nitrogen

oxides formation limits the amount of NOX formed. The following method is used for reducing peak cycle

temperature and thereby reducing NOX emission.

5.2 Exhaust gas Re circulation:

|

| Figure 5.1-Schematic diagram of EGR (www.yanmar.com) |

In the internal combustion engines, exhaust gas recirculation (EGR) system is basically a simple method of reducing Nitrogen Oxides (NOX). This system recirculates some of the exhaust gases back to the Engine cylinder. These exhaust gases dilute O2 incoming air stream and include some inert gases which can absorb excessive heat generated in the engine cylinder, thus limiting the peak in-cylinder temperatures. At low temperature NOX are not produced in the engine cylinder.

Exhaust gases re-circulated to

the engine should be 5-15% only in the total intake volume. This maximum

quantity is limited by the need to sustain continuous flame during combustion. Excessive EGR in poorly set up applications can cause

misfires and partial burns.

5.2.1 Cooling system for Exhaust Gas Recirculation:

The exhaust gas drawn off for recirculation has a temperature of around 650 degrees Celsius. It is therefore far too hot to be fed directly into the cylinders; it would increase the temperature of the combustion chamber even further, thereby defeating its actual purpose — that of reducing nitrogen oxide formation by lowering the combustion temperature. For this reason, the exhaust gas is first cooled to around 120 degrees Celsius.

5.3 Effect of EGR on NOX and HC formation

Exhaust gas recirculation system

limits the amount of NOX by lowering the temperature of the engine.

While performing its function EGR system deposits more carbon (C) content due

to reduction in oxygen intake. These effects are clearly shown in fig (2).

|

|

From the graph it is concluded that as the percentage of EGR

increases nitrogen oxide formation reduces and formation of Carbon content in

the engine increases.

5.4 Advantages of EGR:

·

NOX

formation reduces.

·

Reduction in

cylinder temperature improves the engine lifetime (especially exhaust valve

life).

·

There is potential

reduction of throttling losses on spark ignition engines at part load.

6. Continuously Variable Transmission (CVT):

6.1 Background:

In automobiles power is generated

by the engine and available at the crank shaft for usage. Problem is that we

cannot supply power generated directly from source engine to the wheels because

we need to alter speed and torque of the vehicle. Initially, we need high

torque but low speed to start the automobile but as the vehicle continue its

journey we need to switch from low speed to high speed of vehicle and less

torque. Thus we need a system which will enable us to perform this function,

such a system is called is called transmission system. Basic job of

transmission system is switching between high and low speeds, and corresponding

torque.

Transmission system is simply

refers to as gearbox which consists of gears and gear trains in order to

accomplish the conversion of speed and torque from rotating power source to

other device. When an automobile starts, engine rotates at very high speed.

This high speed is inappropriate for starting, stopping and slower travel. Transmission

limits this high speed to the low speed increasing torque in the process by

altering the gear number.

In transmission system, there are certain numbers of gears which can be switched in order to perform its job. Switching of gears can be done manually or automatically. In case of manual transmission system there is driver operated clutch which is engaged or disengaged by foot pedal in automobiles and thus regulates torque transfer from engine to transmission, and gear selector operated by hand. Schematic diagram of Manual transmission system is shown in fig (4).

Main disadvantage of manual

system is that for every gear change, jerk is felt. Driving in bumper-to-bumper

traffic in large cities can be both a nuisance and a wallet-breaker if you own

a manual transmission. Those familiar with driving a manual transmission in

urban areas often complain about leg cramps and increased workload when driving

in traffic. With a third pedal to actuate during shifts, a manual transmission

can quickly become annoying. Automatic transmissions are considerably easier

and more convenient to drive in stop-and-go traffic.

6.2 CVT:

|

| Figure 6.2-Engine connected with CVT (www.audiworld.com) |

6.3 Working of CVT:

|

| Figure 6.3-variation in pulley diameter (practicalmotoring.com.au |

|

| Figure 6.4-Schematic diagram of CVT |

This is the same thing a conventional transmission does,

but instead of changing the ratio in stages by shifting gears, the CVT

continuously varies the ratio -- hence its name

6.3.1 Effect of CVT on vehicle speed and fuel

consumption:

| |

|

|

| Figure 6.6-variation in speed for CVT and General AT (www.quora.com) |

In case of manual transmission system gears are to be changed alternatively,

thus at every gear change there is decrement of speed and then increment which

causes inconvenient. In auto transmission although there is no need to change

gears manually but a jerk is felt during gear change due to fluctuation in

engine speed. Following Figures shows comparison between CVT

and Auto/Manual transmissions

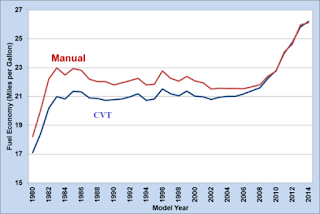

CVT not only improves speed variation over time but also it makes automobile fuel efficient. An automobile having CVT consumes less fuel than manual transmission system. This is because, in CVT there are not number of gears mounted on shaft rather pulley-belt arrangement is present which offers less frictional effects and thus less fuel is consumed. Comparison is shown below for CVT and Manual systems over years.

|

| Figure 6.7: Fuel Consumption for CVT and Manual systems |

7. GDI (Gasoline Direct Fuel Injection)

It is a Fuel injection system in

which gasoline is directly injected into the cylinder of a gasoline automobile

engine. Usually we know that gasoline is injected into the engine after mixing

it with air in carburetor.

|

| Figure 7.1- Fuel injection system using GDI |

7.1 Working of GDI

Gasoline

engines work by sucking a mixture of gasoline and air into a

cylinder, compressing it with a piston, and igniting it with a spark. The

resulting explosion drives the piston downwards, producing power. This

conventional sort of system has some drawbacks as well which are being

discussed in section. Therefore, some modifications in the fuel injection

system of gasoline automobile system was made and gasoline direct injector was

introduced. In this system the gasoline is directly injected into t6he engine

while compressed air is drawn either by supercharging, by turbocharging or

using any air induction method.

After filtering the fuel from

the fuel filter the pressure of the fuel must be raised. This is being done by

a fuel pump which is connected to the ECU (Engine control unit). The

pressurized fuel is now ready to be pumped into the engine via an electrically

operated fuel injector.Schematic diagram of GDI system is shown

7.2 Need of GDI system:

●

At low speed or while cranking, the mixture supplied by a

carburetor is not much enriched so it

will not ignite properly and for its enrichment, at such conditions some

arrangement in the carburetor was required.

●

Atmospheric pressure can change the working of carburetor because

at different atmospheric pressures the amount of air entering the carburetor

may vary.

●

It gives the proper mixture at only one engine speed and load,

therefore, suitable only for engines running at constant speed.

●

Maintenance costs of carburetor are higher (Mechstuff4u.com. (2018)).

Above

mentioned problems can be solved by using Gasoline direct injector system which

controls emission level, improves the fuel consumption efficiency of engine and

increase the power output of the automobile.

7.3 Comparison between GDI system and Carburetor:

7.3.1

Speed vs. Power output:

The speed vs. power output curves

of engines with carburetor and with GDI system have been shown below:

7.3.2 Speed vs. Power output: |

7.3.3

Speed vs. Fuel consumption Graph:

|

|

|

7.4 Advantages of GDI system:

7.4.1 Power Output

With

the exception of some high end modified vehicles, fuel injection usually offers

a much better power output and performance than a standard carburetor-based

vehicle.

7.4.2 Fuel Efficiency

Because

fuel injection is usually controlled by a vehicle's electronic control unit or

car computer, fuel consumption is usually managed much better than with a

carburetor. It almost always results in better fuel efficiency.

7.4.3 Emissions Performance

With

better fuel efficiency comes better emissions performance. Fuel injected

vehicles produce far fewer carbon based emissions than vehicles with

carburetors.

7.4.4 Ability to Accommodate Alternative Fuels

Vehicles

that use direct fuel injection are better equipped to handle alternative fuels,

and fuels with additives that are designed to help keep your car engine clean.

7.4.5 Drivability and Smooth Operation

Vehicles

that use fuel injection rather than a carburetor usually drive much smoother,

because fuel flow is better managed and more consistent.

7.4.6 Diagnostic Capability

Because

direct injection is regulated by your car's computer, problems with fuel

injection can easily be diagnosed with a simple computer diagnostic test

7.5 Automobiles using GDI technology:

●

Sport car 9

●

In 1955, launch of Mercedes 300 SL with direct

injection.

●

First serial application with 4 stroke engine.

●

1996: First stratified gasoline direct injection

on Mitsubishi Galant

●

1998: Toyota D4

●

1999: Renault IDE (Lambda 1 with high EGR rate)

●

2000: First Bosch gasoline direct injection VW «

FSI » engine

●

2000: PSA HPI engine

●

2005: PSA Prince engine THP

●

The Audi R8 4.2l FSI gained the victory in 2001

of the famous race “24 heures du Mans” with the gasoline direct injection

technology.

8. EFI (Electronic Fuel Injection) System

Fuel injection is defined

as the introduction of fuel in the automotive engine by the means of a fuel

injector. Fuel injectors are mechanically operated as well as electronically

operated. Mechanically operated fuel injectors have some disadvantages. In 1967,

first serial application of the indirect injection controlled by electronics

(VW 1600). By the introduction of electronic control system in automobiles, the

problems of emissions and fuel wastage has been reduced (2018. Jalopnik.Com.

https://jalopnik.com/how-electronic-fuel-injection-works-499902815).

8.1 Functions:

It

can be considered as the brain of the automobile. Engine Control Unit (ECU) performs four

basic operations in the smooth running of an automobile:

●

ECU controls the fuel

mixture.

●

ECU controls idle speed.

●

ECU is responsible for

ignition timing

●

ECU controls valve

timing.

8.2 Working:

ECU

can be considered as a black box. Several receivers and sensors collect data

for ECU and there is a microprocessor which is actually the part of ECU which

processes the data provided by the various sensors then it sends the

information to actuators. Following fig

It

can be seen form fig that there are several sensors like oxygen sensor, Air

temperature sensor, Engine temperature sensor, MAP sensor and other receivers

and sensors are there. Similarly there are some actuators which are performing

useful work. All sensors and actuators are linked by a microprocessor.

Microprocessor receives data from the sensors and then gives instructions to various

actuators to perform useful work.

8.3 Disadvantages of Mechanical fuel injection system:

Mechanical

fuel injectors are operated on the principal that pressurized fluid exerts

pressure on the valve to open it. They have the limitation on delivering

optimal fuel to the engine. Their

incompetency to provide optimum amount of fuel is due to the fact that these

injectors are affected by following parameters:

●

Engine’s speed and

●

Load

●

Atmospheric and engine temperatures

●

Altitude

●

Ignition timing

.

9. Turbocharging

Turbocharging is an important process through which

sufficient air is forced in the cylinder of an engine. It is a forced induction systems. It provides air to

the engine which produces more power as the volumetric efficiency of the

engine.

9.1 Turbocharger:

It is a forced

induction system which forces the incoming air of the atmosphere by the push

provided by the outgoing exhaust gases. It is actually a turbine based forced induction part

of the automobile engine that increases the efficiency of the engine.

9.1.1 Need of turbocharger:

As we know that the efficiency of engine depends upon

the volumetric efficiency of the engine. The volumetric efficiency of the

engine can be increased using multiple solutions.

We

can use following means to achieve our goal:

●

By ducting intake air from outside of the engine

compartment

●

By changing the time for which the valves opens

●

By supercharging

●

By turbocharging

All the above-mentioned methods except turbocharging

does not give efficient system (Ezez. 2018).

They can maintain the system to some extent but they are not much effective

ways therefore the invention of turbocharger took place. We can have volumetric

efficiency close to 100%.

9.1.2 Parts:

Turbocharger

consists of following parts:

●

Compressor

●

Turbine

●

Control system

●

Bearing system

9.1.3 Working:

The

spindle of turbo charger is attached with two wheels one is compressor wheel

and the other one is the turbine wheel. When outgoing air is passed through the

turbine wheel it makes the spindle rotate and the compressor wheel forced the

incoming air to come into the cylinder.

9.1.4

Advantages of Turbocharger:

9.1.5

Future work:

In

future we are looking for the replacement of gasoline with some other fuels. In

some countries gasoline has been partially been replaced by ethanol but all

over the world gasoline is still a fuel which is being used in excess. The

following graph sows the consumption of ethanol in US.

|

| Figure 9.5-Production of carbon dioxide through various sources |

We want to replace gasoline because of a number of factors.Gasoline increases the emission rate of CO2.The following graph clearly shows this claim.

Oil

and Gasoline Are Not the Only Things Causing Climate Change, but They Are Among

the Biggest.

Other

improvements in fuel systems are as follows:

- Fuel Pump Relays

- Modern Fuel Pumps,

Filters, and Regulators

- Pulse-Modulated Fuel

Pumps

- Fuel Delivery System

Sensors

- Fuel System

Diagnostics ("Modern Fuel Delivery Systems - Know Your Parts".

2018)

10. Latest Research in Automobiles

In this section the research review of two research papers

is being presented.The research paper, which we have

studied regarding our thermodynamic Project are

International

Journal of Engineering Research and Technology.

ISSN

0974-3154 Volume 6, Number 3 (2013), pp. 343-350

©

International Research Publication House

http://www.irphouse.com

In

this paper researcher highlights the technical aspects and the working of the

advanced technologies used in the present or can be used in the future

automobiles. The technologies that are discussed in this paper are Variable

valve timing, Valve-electronic Engines , Downsizing and Turbocharging, Advanced

Combustion Modes, Hybrid/Electric

Vehicles, Fuel Cells, Weight Reduction Materials, Alternative Fuels, Batteries

and Energy Storage, 42 volt system, Drive by wire Technology, Camless engine,

Exhaust gas recirculation, Sterling engine opposed piston engine, Split cycle

engine, Free piston engine and Wankel rotary engine

A critical analysis with the

advantages and disadvantages of these technologies are made in the paper. A

final conclusion is drawn that once these technologies are in the market they

will not only help in providing better modes of transport but will also help in

reducing our dependence on conventional fuels.

Different

future technologies were studies and there benefits were presented along with

their working. Once these technologies become fully functional it will not only

make the travelling part of human comfortable but also reduce our dependence on

conventional fuels. It has been observed that these technologies are also environment

and user friendly.

Proceedings of the World Congress on

Engineering 2008 Vol II

WCE 2008,

July 2 - 4, 2008, London, U.K.

In

this research paper researcher highlights some of the biggest advances in the

field of automotive technology in the past 10 years have come in the area of

safety. Spurred by the improvements in the microprocessor speed,

miniaturization, and software development, the automobile continues to evolve.

In this new approach proposed, researcher going to have an electronic and a pneumatic

circuit to automatically control the traction of the vehicle. During ordinary

conditions, when the vehicle is driven down a straight road, or if the

difference between speeds of the two (rear) wheels is below a specified limit,

no signal will be generated by the electronic circuit. This helps the vehicle

negotiate the turns with better traction control as differential action is

unaltered. But if the difference between speeds is beyond a specified limit,

the signal will be generated by the electronic circuit which will actuate the

pneumatic circuit. This causes gradual braking on the faster wheel until it

gains traction. Hence, the wheels will never lose traction.

This system ensures a

reduction of more than 50% in the capital investment as compared to the already

existing systems can tilt the scales in the favour of the manufacturing company

and eventually the cost conscious consumer

The

system can be successfully incorporated in vehicles having pneumatic/hydraulic

braking system, with a view to provide improves traction. It can be put to use

in especially All Terrain Vehicles (ATV) and vehicles operating in high

altitude areas (vehicles for military application) where snow causes excessive

loss of traction. This system ensures a reduction of more than 50% in the

capital investment as compared to the already existing systems which ensures

the cost effectiveness of the endeavor.

11. Conclusion:

In modern world we are working on RAMS (Reliability,

Availability, Maintainability and safety). We are much interested in

determining the facts and figures. It becomes a part of past when nations are

dominant due to their oil reservoirs today developed world has started

gathering data and implement in their various industries such as automobile industry.

Future of automobile industry is also going to be bright due the field of IT.

We have developed many embedded systems like ECU discussed already. Putting all

this in a nut shell, we can conclude that the application of the knowledge of

engineering and statistics the automobile industry will be the brightest

industry in future due to its revolutions.

12.

References:

</ br>

</ br>

</ br>

12.

References:

1.

"Hybrid

Vehicle". 2018. En.Wikipedia.Org. https://en.wikipedia.org/wiki/Hybrid_vehicle.

2.

"What Is A

Hybrid Car And Should You Buy One?". 2018. What Car? https://www.whatcar.com/news/hybrid-car/.

3.

"Variable

Valve Timing". 2018. En.Wikipedia.Org. https://en.wikipedia.org/wiki/Variable_valve_timing.

4.

"Exhaust

Gas Recirculation". 2018. Dieselnet.Com. https://www.dieselnet.com/tech/engine_egr.php.

5.

"Continuously

Variable Transmission". 2018. En.Wikipedia.Org. https://en.wikipedia.org/wiki/Continuously_variable_transmission.

6.

2018. Jalopnik.Com. https://jalopnik.com/how-electronic-fuel-injection-works-499902815.

7.

Fast, Omer, and

Matthias Michalka. 2007. The Casting.

Köln: Verlag der Buchhandlung Walther König. http://www.ijmer.com/papers/Vol3_Issue2/AM32674677.pdf.

8.

Mechstuff4u.com.

(2018). Advantages and disadvantages

of carburetor. [online] Available at: https://www.mechstuff4u.com/2016/12/advantages-and-disadvantages-of_25.html

[Accessed 25 Apr. 2018].

9.

"Modern Fuel

Delivery Systems - Know Your Parts". 2018. Know Your Parts. https://www.knowyourparts.com/technical-resources/fuel-system/modern-fuel-delivery-systems/.

Post a Comment